→ 30 % cost savings

→ 5 % more battery capacity

→ 100 % fail-safe

→ Power supply in case of power cuts

→ 70 % reduced energy waste

→ 7 years guarantee

→ A self-sufficient energy supply

→ 95 % efficiency

→ Intelligent charge management

→ Kicks in during power peaks

→ Industry and manufacturing

→ Electromobility

→ Building sites or mining

→ Telecommunications

→ Residential complexes

→ Quarter storage

→ Governmental regulations around CO2 emissions have increased dramatically.

→ Roll-out can help to reach worldwide climate goals.

→ The footprint of every lithium-ion e-car battery can be improved.

→ The lifespan of the batteries is being extended until recycling.

→ Better EUR/kWh price situation by deploying 'used' batteries.

→ Significant governmental support existing and more to be provided.

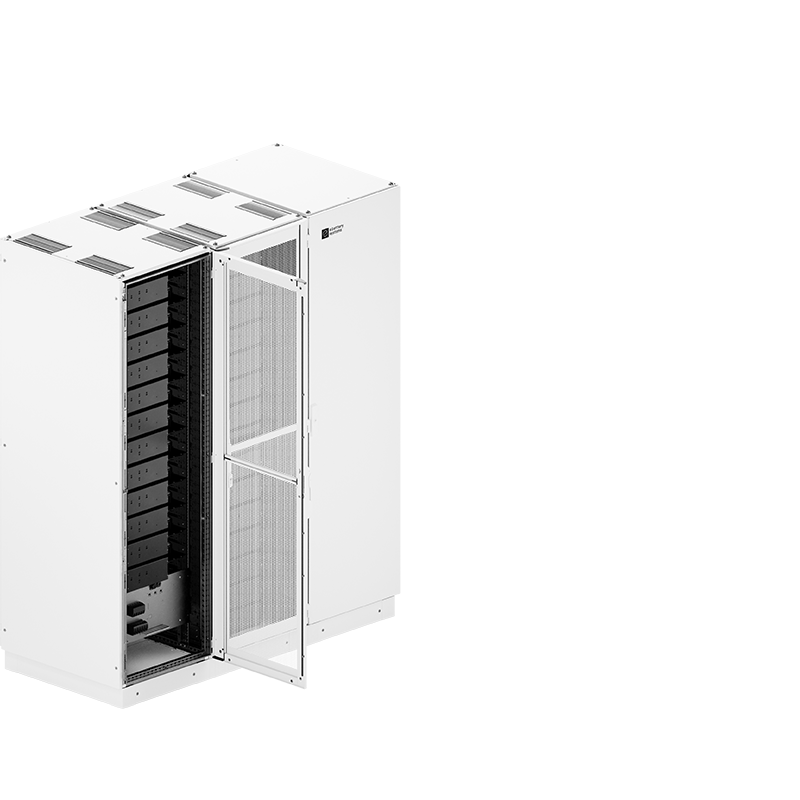

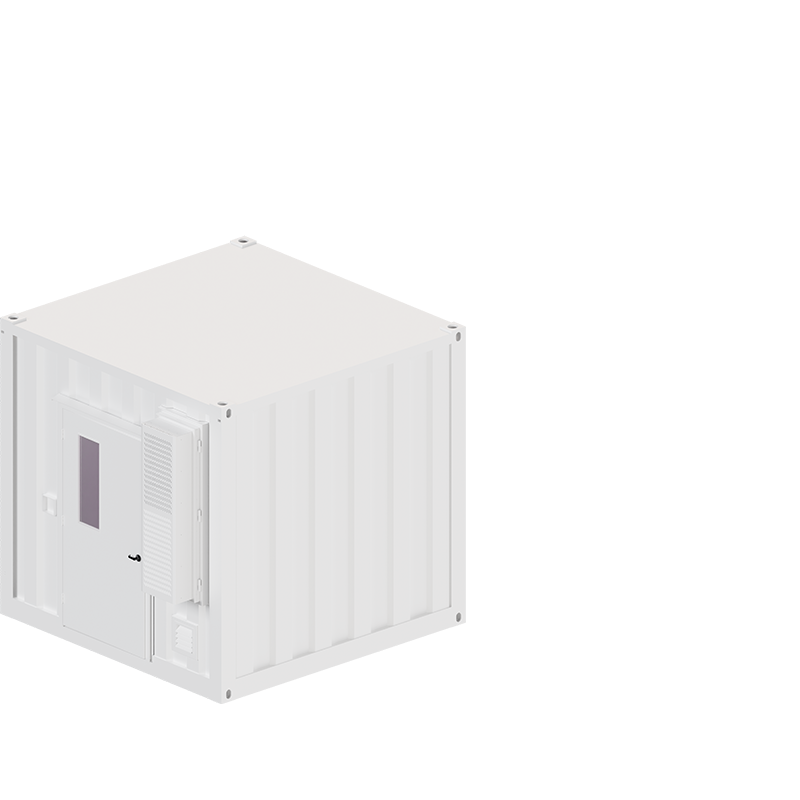

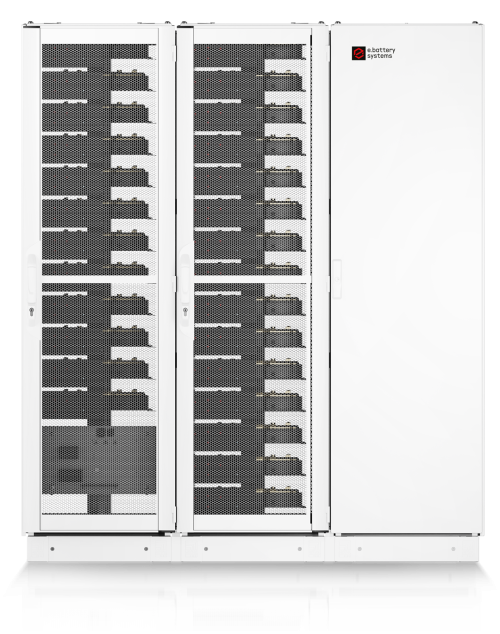

We are setting the new standard for large-scale battery storage systems.

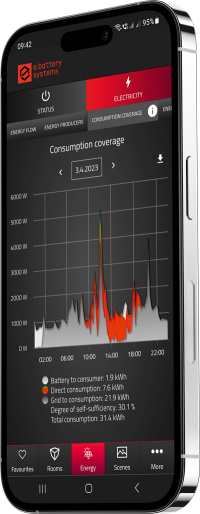

Track and control your energy consumption, energy sources and energy storage system in real time with our energy management system.

Accessible anytime, anywhere.