- Monitors cell voltage

and temperatures - Oversees charging

and health status

Our Battery Management Systems:

BMS

AM 12s

This modular Battery Management System is ideal for applications with a high requirement for monitoring. Thanks to a slide-in plug connector, connecting with a vehicle is simple and safe when faced with possible warped or impaired points of contact.

AM BMS 12s at a Glance:

Use and Handling:

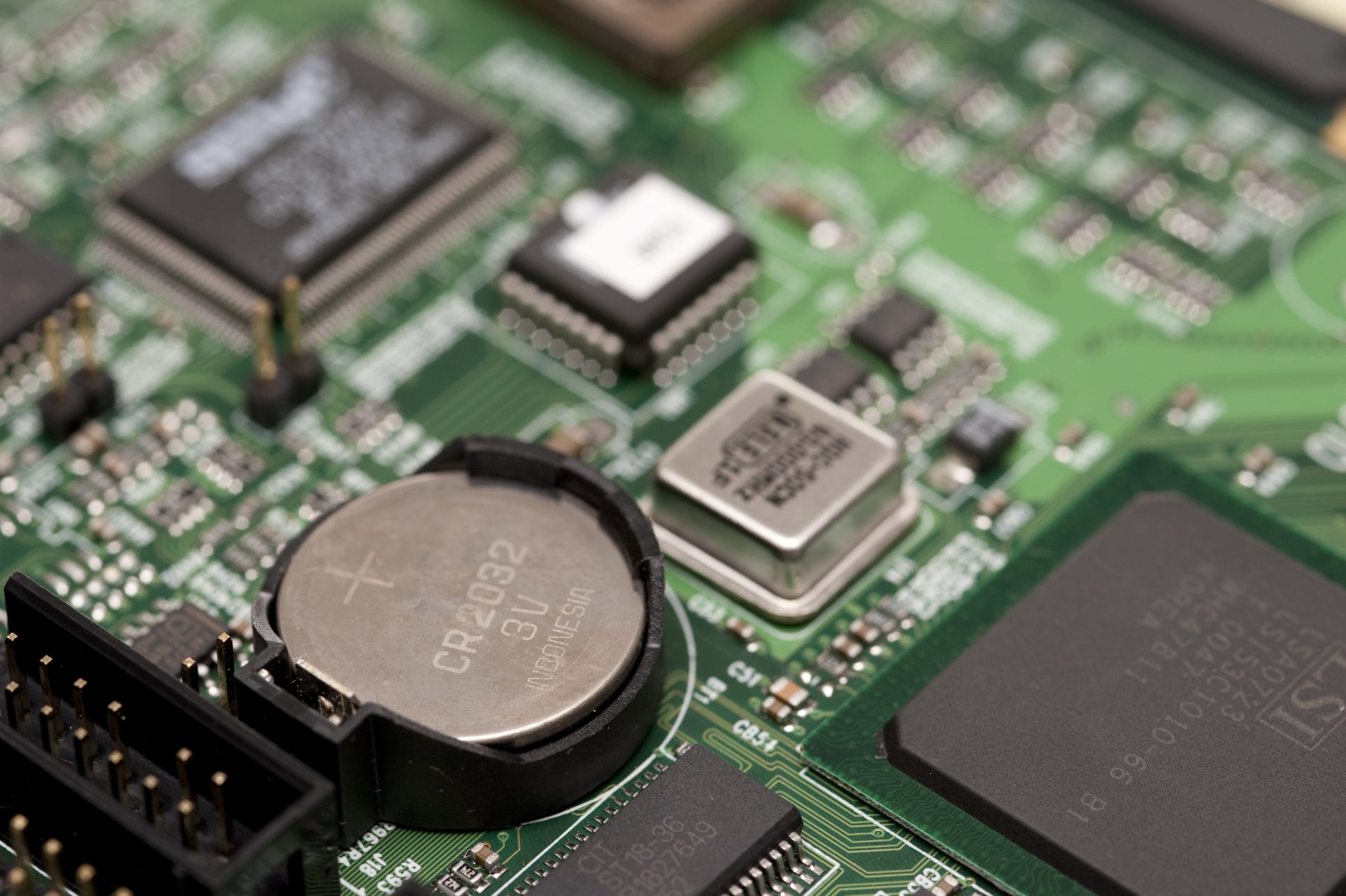

The BMS measures voltages of 1 – 4.2 V per cell and supports all common lithium technologies such as NMC, LiFePo4, LTO, etc. Computer-based monitoring software makes monitoring of the battery packs inherently manageable and user-friendly. It is entirely up to the user which parameters of the Battery Management System are shown. Programming is simple and intuitive thanks to USB Type-C and ST-Link, and four LEDs are onboard to display (SoC) State of Charge. The BMS tested by AOI and Flying Probe is assembled using SMD technology.

Areas of Application:

AM BMS 12s at a Glance:

- Measures 12 cells in series

- Equipped with 2 temperature sensors

- Includes sleep mode to optimize power usage

- Power levels with bidirectional activation for 40A peak and 20A continuous current

- Pre-charge with short-circuit protection

- Integrated current sensor

- Analog shutdown of the output stage in case of overcurrent, overvoltage and overheating

Use and Handling:

The BMS measures voltages of 1 – 4.2 V per cell and supports all common lithium technologies such as NMC, LiFePo4, LTO, etc. Computer-based monitoring software makes monitoring of the battery packs inherently manageable and user-friendly. It is entirely up to the user which parameters of the Battery Management System are shown. Programming is simple and intuitive thanks to USB Type-C and ST-Link, and four LEDs are onboard to display (SoC) State of Charge. The BMS tested by AOI and Flying Probe is assembled using SMD technology.

Areas of Application:

- FTS

- AGV

- Robotics

- Automotive

- Scooters

- E-Bikes

BMS

AM 30s

This modular Battery Management System is ideal for applications with high mechanical loads and high currents. A combination of analog and software-based safety mechanisms makes this BMS a veritable allrounder in a wide range of use cases.

AM BMS 30s at a Glance:

Environmental Specifications:

Use and Handling:

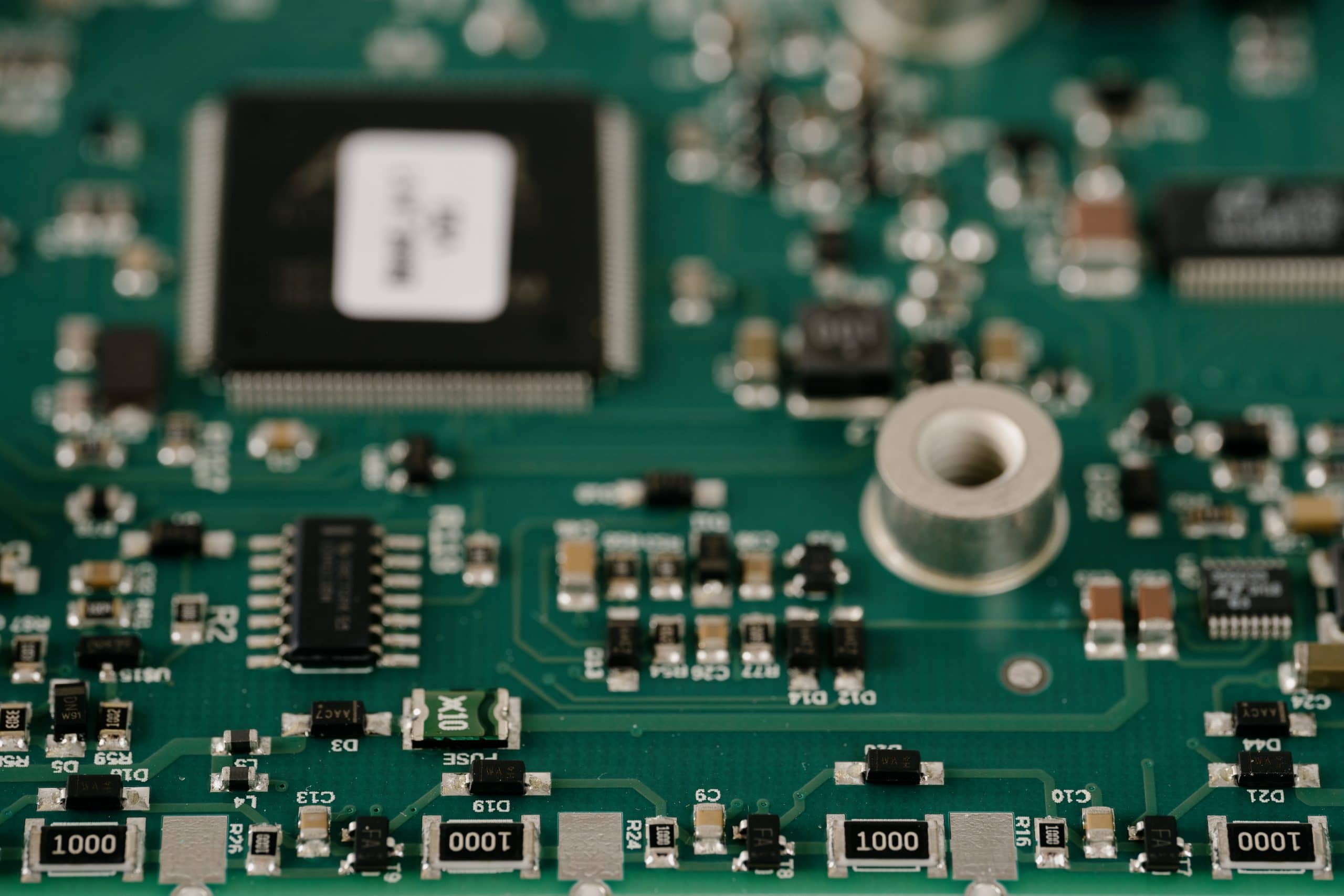

In order to process signals, measurements and interface communication, the BMS is comprised of multiple master boards. There is a master for each part of the battery pack, and each part in turn may consist of several battery modules each possessing up to 14 cells. There is one slave per battery module, connected to the master via CAN and tasked with measuring and balancing the voltage and temperature of the battery cells.

Last but not least, there is also the multi-master configuration which can coordinate multiple master sub-systems. A system master becomes the higher-level system that then controls external pre-charges and directs the other master systems.

AM BMS 30s at a Glance:

- Measures up to 14 cells in series

- 6 NTC10K temperature sensors

- 3 analog inputs (0 - 10 V)

- 4 digital output galvanic 2 A 130 V fuse

- 1 digital output galvanic 1 A power box

- 1 CAN out galvanic 125 - 1 M.

- 1 CAN intern

- 2 LED OUT

- Analog current sensor (2 channel)

- Wake-up = Taster/12 V/CAN

Environmental Specifications:

- IP class: IP40

- EN60204 compliant

- Operating temperature: -10 °C bis + 60 °C.

- Storage temperature: -30 °C bis + 80 °C.

- Humidity class F, air humidity < 85 %

- Air-conditioned, with additional internal cooler fan

Use and Handling:

In order to process signals, measurements and interface communication, the BMS is comprised of multiple master boards. There is a master for each part of the battery pack, and each part in turn may consist of several battery modules each possessing up to 14 cells. There is one slave per battery module, connected to the master via CAN and tasked with measuring and balancing the voltage and temperature of the battery cells.

Last but not least, there is also the multi-master configuration which can coordinate multiple master sub-systems. A system master becomes the higher-level system that then controls external pre-charges and directs the other master systems.